EVOH Resin Thermostability High Barrier Material Food Packaging Plastic

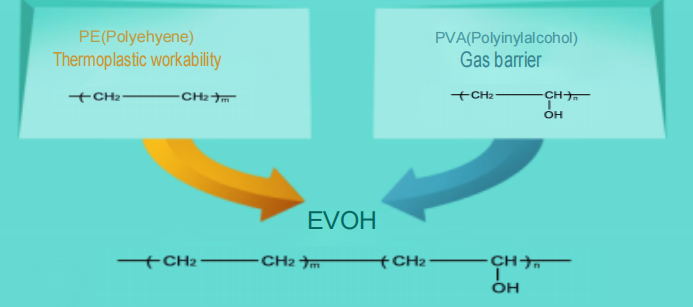

Ethylene-vinyl alcohol copolymer resin EW series products are thermoplastic high-barrier resins developed by Kemis’ own technology. They have good high-barrier properties, transparency, and molding processability. They are one of the ideal raw materials for packaging materials, automobile fuel tanks, and pipeline materials. It fills the gap in this type of products in mainland China, and its oxygen barrier performance is 10,000 times that of LDPE.

Kemis is the brand merchant of Sinopec Chemicals- A professional EVOH Manufacturer, guarantees the best quality in China and fast delivery, providing a one-stop service in the chemical supply chain.

Molecular structural formula:

Product standards

| Item | Index | Testing standard methods | ||

| EW-3201 | EW-3801 | |||

| Melt Index * (g/10min) | 1.5-2.5 | 1.5-2.5 | GB/T3682-2000 | |

| Chromaticity ≤ | 20 | 20 | ||

| Volatile matter (W%) ≤ | 0.3 | 0.3 | ISO14663-2 | |

| Ethylene content (mol%) | 30.0-34.0 | 36.0-40.0 | ISO14663-2 | |

| Density (g/cm³) | 1.10-1.20 | 1.10-1.20 | GB/T4472-2011 | |

| *190°C,2160g | ||||

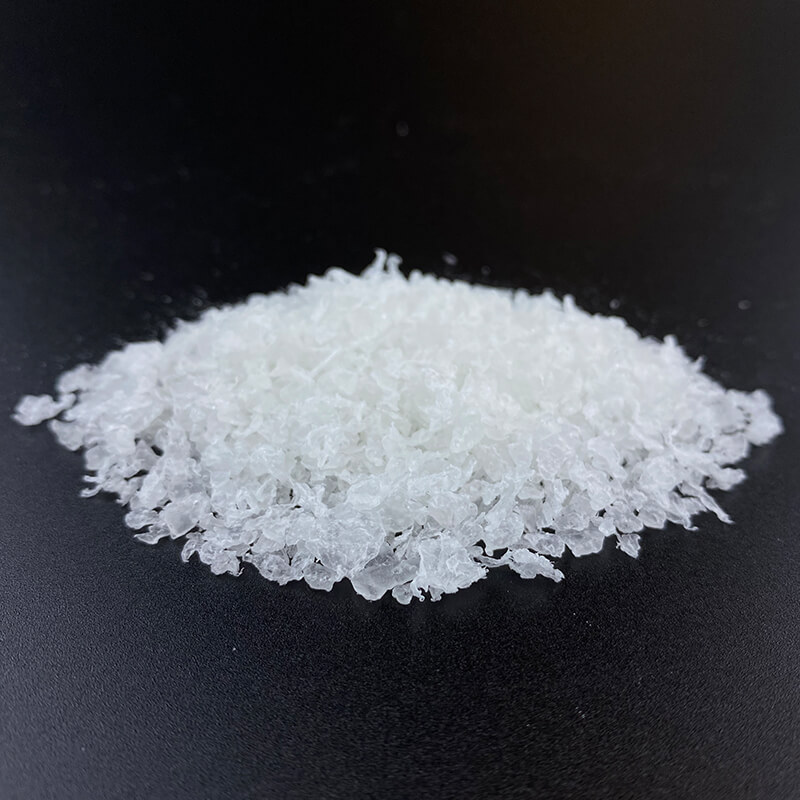

Properties:

| Appearance | Cylindrical or ellipsoidal particles |

| Colour | White, transparent or semi transparent |

| Melting point | 140℃-200℃ |

| Density | 1.10-1.22 |

| Melting point | >300℃ |

| Water solubility | Insoluble |

| Solubility (other) | Soluble in dimethyl sulfoxide |

Applications:

Barrier packaging material: EVOH resin EW series products are widely used for barrier packaging in food, medicine, daily chemical products, and other fields due to their excellent oxygen resistance and thermoplastic processability.

1. Film use:

| Forming method | Structure (Outer-Inner) | Packaging material properties | Application |

| T-die casting method or blown film co-extrusion | PA/EW/EVALLDPE/Tie/EW/EVA PP/Tie/EW/Tie/PP | Barrier, transparency,tear resistance, puncture resistance | Raw meat, ham, sausages, processed fish products, etc |

| Co extrusion and composite | PA/EW/PA/LDPE | Barrier,tear resistance,puncture resistance | Vacuum fitting bag |

2. Purpose of plastic bottles and boxes

| Forming method | Structure (Outer-Inner) | Packaging material properties | Application |

| Co extrusion hollow forming | PP/Tie/EW/Tie/PPHDPE/Tie/EW/Tie/HDPE PET/EW/PET | Barrier, oil resistance,transparency, solvent resistance, high strength | Juice, tomato sauce, magnetic acid drinks, industrial drugs, gasoline |

| Co extrusion and composite | PP/Tie/EW/Tie/PPHDPE/Tie/EW/Tie/HDPE PET/EW/Tie/PP | Good barrier, fragrance retention, and material strength | Jelly, cream, raw meat,ham, sausages, etc |

3. Pipe use

| Forming method | Structure (Outer-Inner) | Packaging material properties | Application |

| Multi layer tube co extrusion | LDPE/Tie/EW/Tie/LDPELLDPE/Tie/EW/Tie/LLDPE | Fragrance retention, extrusion resistance, and resistance to organic solvents | Cosmetics, toothpaste, floor heating pipes, etc |

Co extrusion composite film: used for packaging raw meat, ham, fish and other products

Co extruded sheet packaging: used for packaging products such as tomato sauce, yogurt, jelly, jam, etc

Co extruded sheet packaging: used for packaging cosmetics, pharmaceuticals, industrial drugs, daily chemical products, etc

Automotive fuel tanks: The EW series products have excellent oil resistance, solvent barrier properties,and are ideal materials for the manufacturing of automotive fuel tanks and other containers.

Floor heating pipes: EW series products have excellent aging resistance, gas resistance and other properties, which can be used for underfloor heating pipes, etc., to play a role in creating a comfortable living space.

Recommended composite materials

| Material type | PTFE | PE | PP | SBR | NR | BR | PS | PVAC | PVC | PET | EP | POM | PA | PAN | EW |

| Solubility parameter | 6.2 | 8 | 7.9 | 8.1-8.5 | 8.1 | 8.5 | 8.5-9.6 | 9.4 | 9.6 | 10.7 | 11 | 11.1 | 13.5 | 15.4 | 19 |

The significant difference in solubility parameters between materials results in incompatibility between EW series products and most olefin polymers, so a bonding layer is necessary. EW series products and PA, PAN do not require a bonding layer.

Processing precautions

Cleaning before feeding:

If switching from LDPE to EW, it can be used directly; If switching from other materials such as PA, PVC, HDPE, PP, LLDPE, etc. to EW, it is necessary to completely replace the resin in the material barrel and mold head with LDPE first, and then use EW.

Resin temperature:

Please note that the temperature setting of the material barrel and die head should not exceed 240 ° C, and the screw speed should be controlled

Detention time:

If the production interruption exceeds 30 minutes, please keep the screw running at low speed or replace it with LDPE.

Parking cleaning:

It is recommended to use LDPE replacement cleaning.

Packaging, storage and transportation

- Packaging: The product adopts multi-layer aluminum plastic composite bags for vacuum packaging, and the packaging specifications and net weight can be determined according to customer requirements.

- Storage: The product should be stored indoors in a dry and well ventilated area, away from heating or heat sources, and protected from moisture, rain, and sun.

- Transportation: The product is non hazardous and should be prevented from scratching or damaging the packaging during loading and unloading. If there is leakage, the resin particles should be cleaned up as soon as possible to prevent slipping. During transportation, it should be protected from moisture, rain, and sun.